THE EARLY YEARS

DVD Running Time: 58 minutes

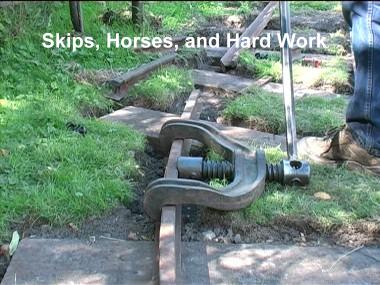

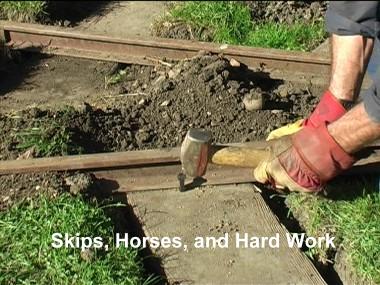

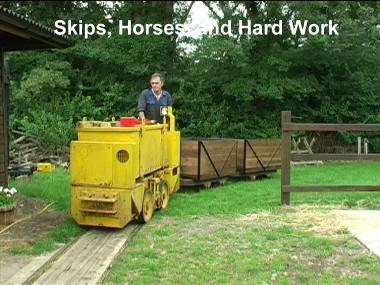

In 2006, 2 small locomotives were purchased with the intention of building a short railway of under a half mile in length, to move horse manure from stables to a temporary muck heap for composting. Although having visited many industrial narrow gauge locations in the past, there was little or no experience of actual track building or loco restoration.

Following a number of interested enquiries regarding how the railway was built and asking for more details, this DVD has been made as the first of 2 DVDs about the Springfield Agricultural Railway. This first production looks at the construction of the railway and obtaining and restoring the first locos on the line, and running the first trains.

Via video footage and pictures over the first 3-4 years, the viewer can see how some of the obstacles were overcome, how the tracklaying was done, obtaining the locos, the locos bursting into life for the first time in many years, obtaining and building rolling stock, and various other activies.

The price is £12.00 which includes post and packing in the UK (other rates for Europe and the rest of the world are shown on the Palpal ordering buttons below). Any profit will be used to continue to maintain and restore the railway and rolling stock. Visitors are usually welcome, but only if arrangements are made in advance (eg; via the 'Contact Us' link on the top menu bar).

Please see below for stills from the production